Imikhakha

- Precision Tooling

Precision Tooling

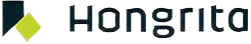

Njengoba sineminyaka engu-35 yokuhlangenwe nakho ekukhiqizeni isikhunta esinembayo esiphezulu, sinesethi yezindinganiso zokuklama isikhunta esiqediwe, siyazi ukuthi singakha kanjani isikhunta esizinzile, esisebenzayo, esihlala isikhathi eside sekhwalithi ephezulu ukuze sisetshenziswe embonini yezimoto, imishini yezokwelapha, ukunakekelwa komuntu siqu kanye nokupakisha.

Ukuzibophezela kukaHongrita ekusebenzeni kahle kwezobuchwepheshe kuyivumela ukuthi ihlale ihamba phambili ekusunguleni izinto ezintsha. Inkampani iqhubeka nokutshala imali ocwaningweni nasekuthuthukisweni ukuze yamukele ubuchwepheshe obusezingeni eliphezulu, obuthuthukisa ikhono layo lokukhiqiza izingxenye nemikhiqizo yepulasitiki enembayo ephezulu.

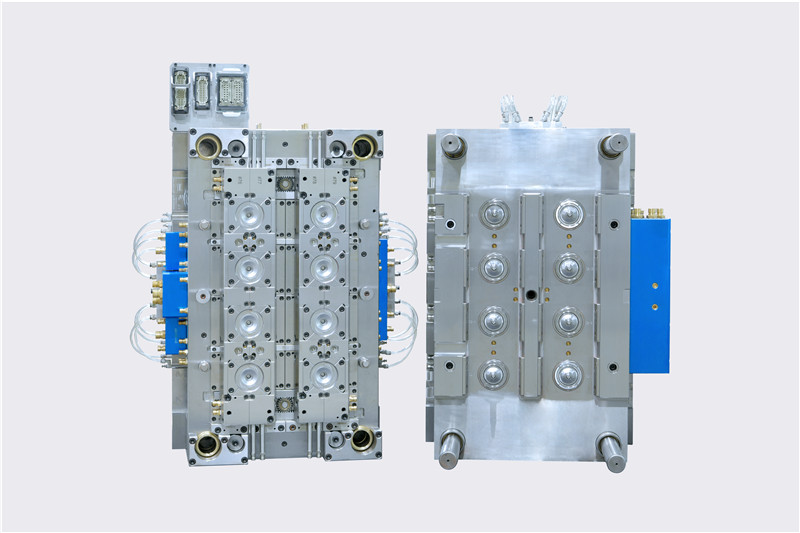

I-Multi-Component Molding

I-Multi-Component Molding: I-Hongrita inokuqonda okujulile kokubunjwa kwezingxenye eziningi, okubandakanya ukuhlanganisa izinto ezihlukahlukene noma imibala ekubunjweni okukodwa ukuze kudale izingxenye eziyinkimbinkimbi nezisebenzayo. Lobu buchwepheshe bubavumela ukuthi banikeze izixazululo ezintsha nezingenziwa ngezifiso kumakhasimende abo.

I-Multi-Component Molding

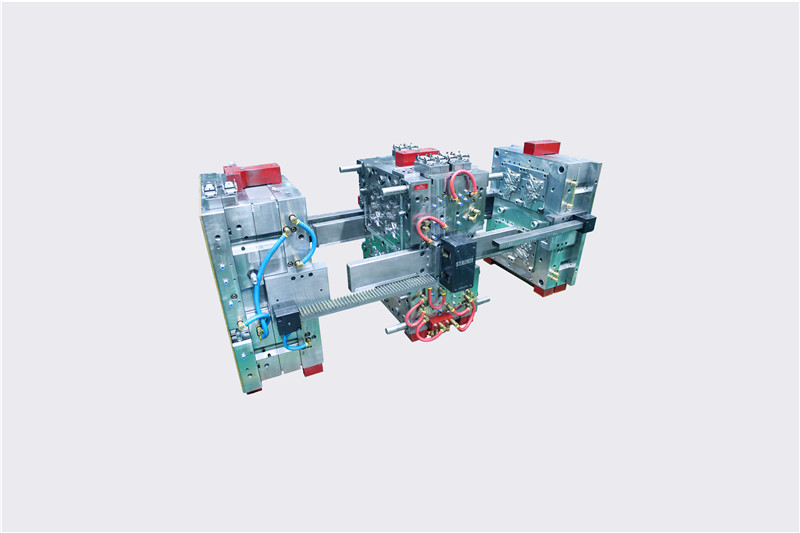

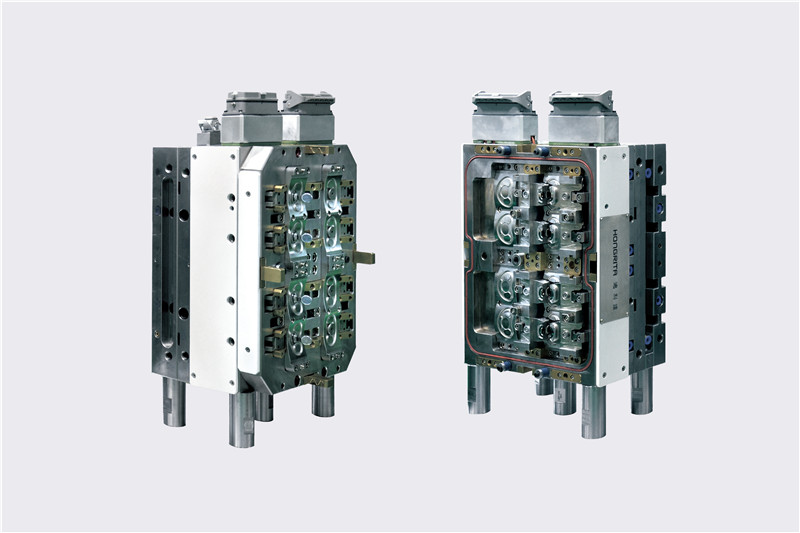

I-Multi-Cavity Mold

I-multi-cavity molds ekhiqizwa yi-Hongrita ingahlangabezana nezidingo ezisezingeni eliphezulu zokwenza ngokwezifiso ikhasimende.Isakhiwo se-modular sesikhunta sisho izinga eliphezulu lokuguquguquka. Ngaphezu kwalokho, ukufakwa kwesikhunta okushintshwayo kwenza isikhunta esiyisisekelo sisetshenziswe emikhiqizweni ehlukahlukene. Ubuchwepheshe bokupholisa obusha kanye nezingubo ezikhethiwe kuqinisekisa ubuncane bezikhathi zomjikelezo nempilo ende yesevisi.

I-Multi-Cavity Mold

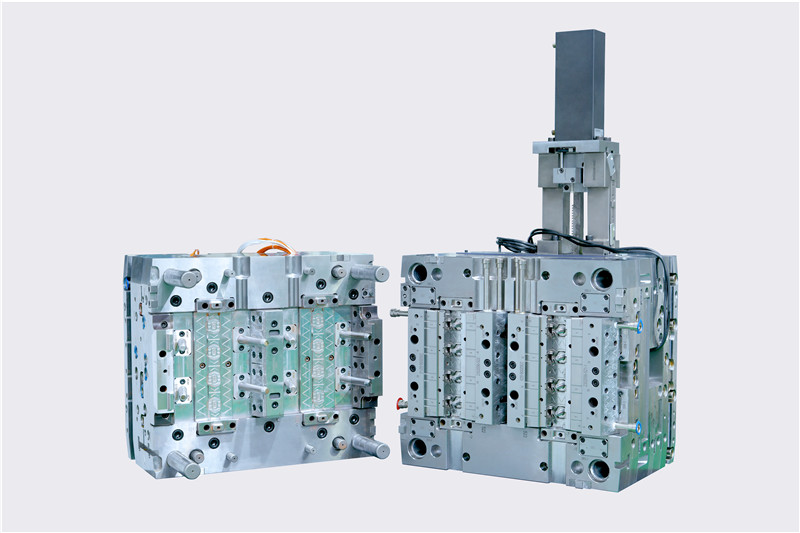

I-LSR Mold

Izibunjwa ze-Hongrita LSR ezinesistimu yokugijima ebandayo ye-valve zakhiwe endlini. Ingasetshenziselwa ukwakha izingxenye ze-LSR eziyinkimbinkimbi kakhulu ezinemininingwane emincane kakhulu nokubekezelelana okuqinile. I-Hongrita ingakwazi ngisho nokuba yingcweti ye-high cavitation LSR & 2-Component LSR/LSR noma i-LSR/Thermoplastics tooling, izimboni ezizuzisayo ezifuna izingxenye ze-silicone zekhwalithi ephezulu kanye nokubumba kwe-silicone esebenza kahle kakhulu.